The GLT quality promise

Our quality promise is deeply anchored in our corporate DNA. However, it is not only the quality of our products that plays a key role for us; our quality awareness is also reflected in all upstream and downstream processes.

Whenever some bearings cannot be supplied from our standard stock program – be it due to unique or non-common dimensions or a specifically required material – we produce them individually according to customer requirements.

Whenever some bearings cannot be supplied from our standard stock program – be it due to unique or non-common dimensions or a specifically required material – we produce them individually according to customer requirements.

Just give us a call, and we will clarify all necessary parameters to be able to submit you an offer and determine the expected delivery time.

The interaction of design, dimensions and material is decisive for the desired properties of the new bearing to be developed. Our development team works closely with our customers to achieve the best possible result.

Whenever a new bearing has to be developed, the engineers of our development team are in demand. Their know-how, experience and creativity are the basis for every individual bearing solution. Always technically up to date, they exchange ideas with those responsible in your company and translate your requirements into functioning solutions.

Without a test phase, it usually doesn’t work. For the production of prototypes, we have high-precision 3D printers that bring the design results into tangible form.

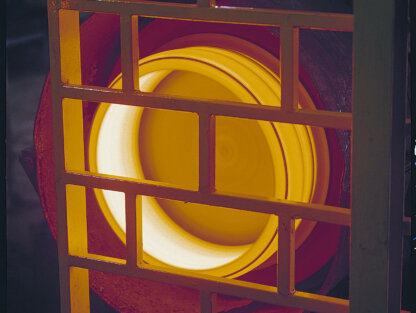

In addition to a large number of materials we can draw on, which have already proven their resilience thousands of times in practice, we develop unique materials for specific requirements, such as our bronze alloy LHG155®.

The requirement profile for new material is defined by a wide variety of parameters, which are either specified by our customers or can be derived together with the customer during the design phase.

We supply “everything from a single source” as a solution provider. For the production of high-quality, attractively priced bearings, the key lies in the optimal networking of our own production and specialized producers with whom we have been cooperating successfully for decades. No matter where or by whom a GLT bearing is manufactured – the quality standard is always the same. We guarantee this through continuous quality testing – from the production site to incoming goods to outgoing goods.