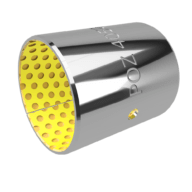

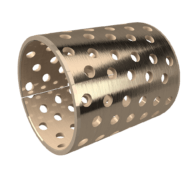

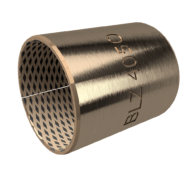

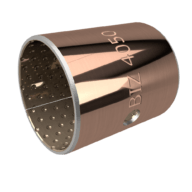

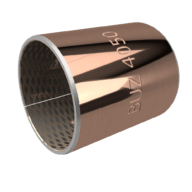

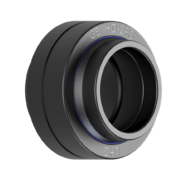

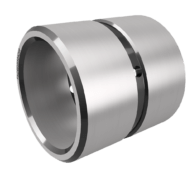

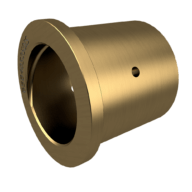

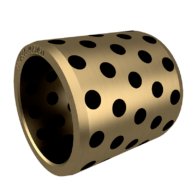

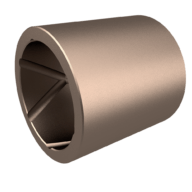

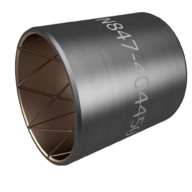

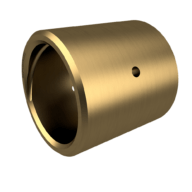

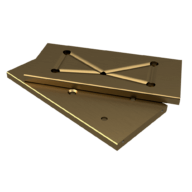

Bearing properties

- BRO-MAS® is a plain bearing requiring maintenance, is suitable for operation in contaminated environments, has good corrosion resistance, and is insensitive to shock loads. Oil or grease lubrication is needed. Additional lubrication grooves or holes significantly reduce relubrication intervals and improve lubricant distribution.