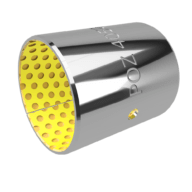

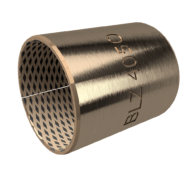

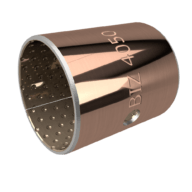

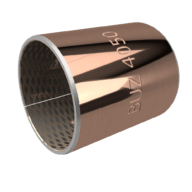

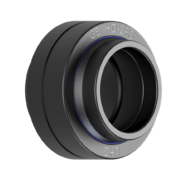

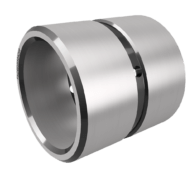

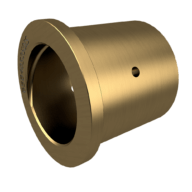

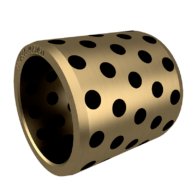

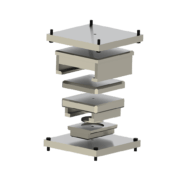

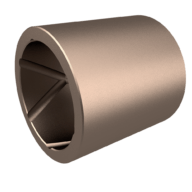

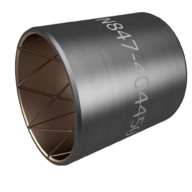

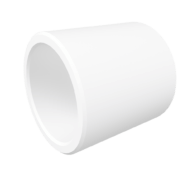

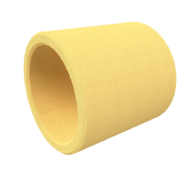

Bearing properties

- GAP-MET®/M is a maintenance-free plain bearing. However, oil or grease lubrication is possible. High load capacity and strength for all slow movement types, suitable for contaminated environments, no moisture absorption, good chemical resistance and good temperature resistance. The parts are mechanically reworkable.