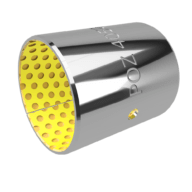

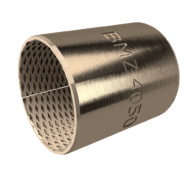

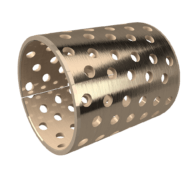

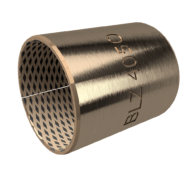

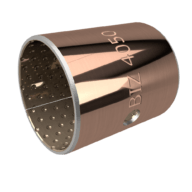

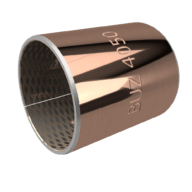

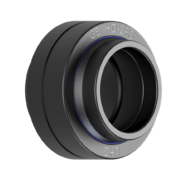

Bearing properties

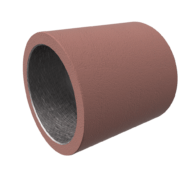

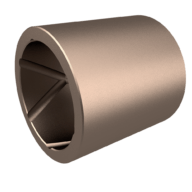

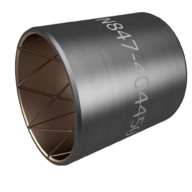

- POM-MET® is a low-maintenance composite sliding bearing with a POM coating. Initial lubrication is required. Both oil or grease lubrication are possible. Due to the lubricant pockets, relubrication intervals are significantly reduced! Suitable for all sliding movements, good load capacity, robust and resistant to dirt.