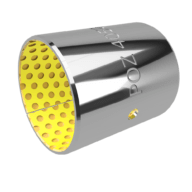

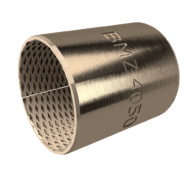

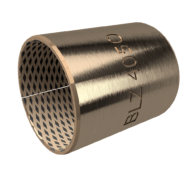

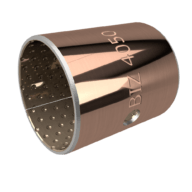

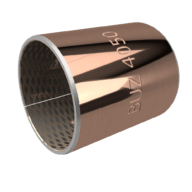

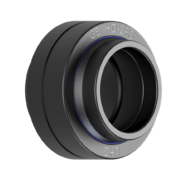

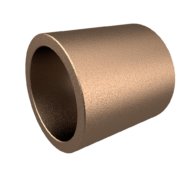

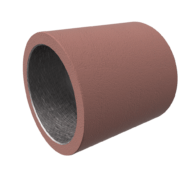

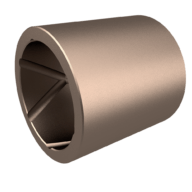

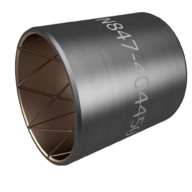

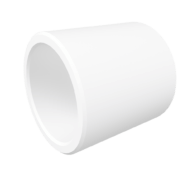

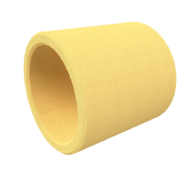

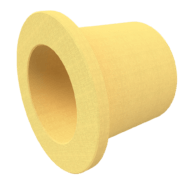

Bearing properties

- COM-KU®/D is a self-lubricating and maintenance-free compound plain bearing. It has good sliding properties and is suitable for loads (also impact loads and with edge pressures). Good damping properties, very suitable for low sliding speeds, good chemical resistance, and long service life. Suitable as a replacement for lubricated bearings.