The GLT quality promise

Our quality promise is deeply anchored in our corporate DNA. However, it is not only the quality of our products that plays a key role for us; our quality awareness is also reflected in all upstream and downstream processes.

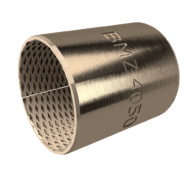

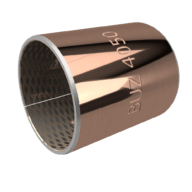

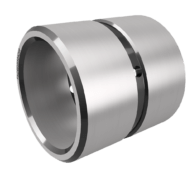

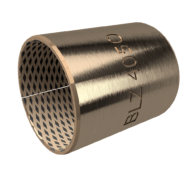

Wrapped composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547

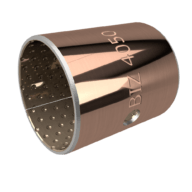

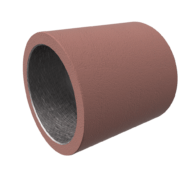

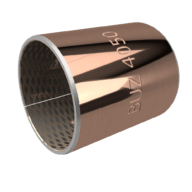

Wrapped composite sliding bearing Bronze / PTFE coated | Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547 | Corrosion resistance | Anti-magnetic

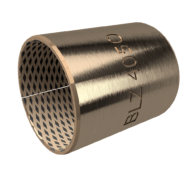

Wrapped composite sliding bearing Stainless steel / PTFE coated | Maintenance-free dry sliding bearing | Corrosion resistance | Chemical resistance | DIN 1494 / ISO 3547

Wrapped composite sliding bearing steel / Special PTFE coated | Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547

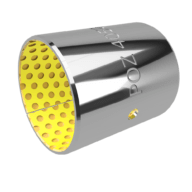

POM-MET® is a low-maintenance composite sliding bearing with a POM coating. Initial lubrication is required. Both oil or grease lubrication are possible. Due to the lubricant pockets, relubrication intervals are significantly reduced! Suitable for all sliding movements, good load capacity, robust and resistant to dirt.

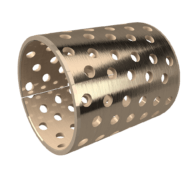

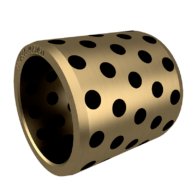

Wrapped bronze sliding bearing with lubrication pockets/ CuSn8P (DIN 17662) | Low-maintenance | DIN 1494 / ISO 3547

Wrapped bronze sliding bearing with lubrication holes/ CuSn8P (DIN 17662) | Low-maintenance | DIN 1494 / ISO 3547

Wrapped composite sliding bearing with lubrication pockets/ CuSn8P & graphite | maintenance-free | DIN 1494 / ISO 3547

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & CuSn10Pb10 | Low-maintenance | DIN 1494 / ISO 3547

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & CuSn10Pb10 & graphite | maintenance-free | DIN 1494 / ISO 3547

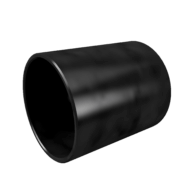

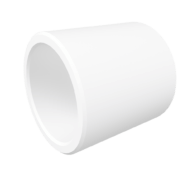

Plastic plain bearing | Maintenance-free | ISO 3547

Maintenance-free and maintenance-required

maintenance-free and maintenance-bound

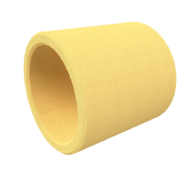

Fibre-reinforced compound sliding bearing in wound technology | Maintenance-free | Highly resilient

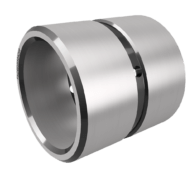

Solid, turned, grinded and hardened steel plain bearing | Requires maintenance

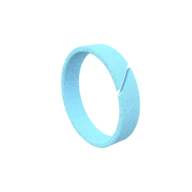

Wrapped spring steel plain bearing | Requires maintenance | DIN 1498 | DIN 1499

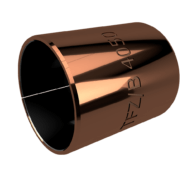

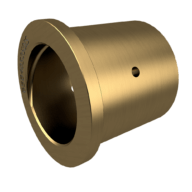

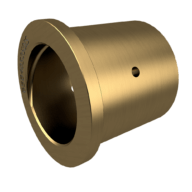

Machined bronze plain bearing | Requires maintenance | DIN 1850 / ISO 4379

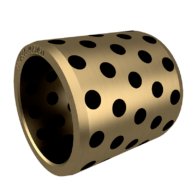

Solid bronze plain bearing | Maintenance-free | With solid lubricant deposits in the sliding surface | Version available with water-resistant solid lubricant

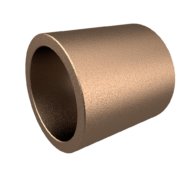

Sintered bronze plain bearings | Maintenance-free | Oil-impregnated | Self-lubricating | DIN 1850 / ISO 2795

Wound all-plastic plain bearing | Maintenance-free | With a sliding layer of PTFE with lubricant additives

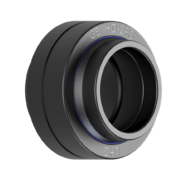

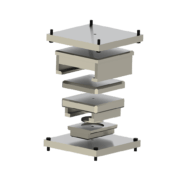

Ready-to-install and maintenance-free sliding support bearing, floating bearing and fixed point

Solid sintered bronze bearing | Maintenance-free | With uniformly embedded solid lubricant in the bronze or iron matrix

Rolled composite plain bearing | Maintenance-free | Steel / graphite bronze | With embedded solid lubricants

Solid, turned, grinded and hardened steel plain bearing | Requires maintenance

Wound all-plastic plain bearing | Maintenance-free | With a sliding layer of PTFE with lubricant additives

Thermoplastic all-plastic plain bearing | Maintenance-free

Fibre-reinforced compound plain bearing in wound technology | Maintenance-free | High load capacity

Machined bronze plain bearing | Requires maintenance | DIN 1850 / ISO 4379

Solid bronze plain bearing | Maintenance-free | With solid lubricant deposits in the sliding surface | Version available with water-resistant solid lubricant

Wrapped composite sliding bearing with lubrication pockets/ CuSn8P & graphite | maintenance-free | DIN 1494 / ISO 3547

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & CuSn10Pb10 & graphite | maintenance-free | DIN 1494 / ISO 3547

Wrapped composite sliding bearing steel / Special PTFE coated | Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547

„creating a world of bearing solutions“

Stahlgruberring 26

81829 München - Deutschland

phone: +49 89 4370799-0

fax: +49 89 4370799-44

E-Mail: info@glt-bearings.com

Wrapped composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547

Then do not hesitate and call us right away or write us a short message.

Our sales team will be happy to contact you!

TEF-MET® is available as: