Newly developed bronze alloy LHG155 exceeds all expectations

The special alloy for the most extreme requirements

In earlier times, simple bronze and brass alloys were often used in various fields of application. These always resulted in increased maintenance and lubricant requirements and led to more extended downtimes due to repairs if the maintenance interval was once again viewed too loosely by the actual operators. In addition, the entire economic working environment has also changed, with higher mechanical demands on people, materials and machines, higher yield requirements or even shorter throughput times, all of which additionally force these regularly required maintenance intervals into even shorter intervals.

At the same time, there are also particularly harsh applications where extremely high loads or even extreme ambient and working conditions have always made it challenging to keep the moving parts of the equipment flexible in these areas with simple Bronze or brass alloys.

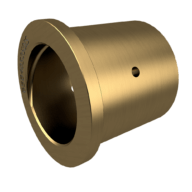

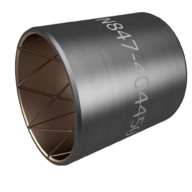

For this reason, GLT Bearings® GmbH in Munich has specialised in finding a better solution for its customers with various solid plain bearing materials and components. In several years of cooperation and joint development work with a foundry for different bronze alloys produced in the centrifugal casting process, we were able to present valid results with our new LHG155®Bronze to some of our first customers in 2018. Further tests were carried out by independent laboratories specialising in material analysis, which, however, uniformly confirmed our own previously determining test results.

For this reason, GLT Bearings® GmbH in Munich has specialised in finding a better solution for its customers with various solid plain bearing materials and components. In several years of cooperation and joint development work with a foundry for different bronze alloys produced in the centrifugal casting process, we were able to present valid results with our new LHG155®Bronze to some of our first customers in 2018. Further tests were carried out by independent laboratories specialising in material analysis, which, however, uniformly confirmed our own previously determining test results.

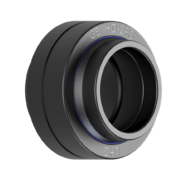

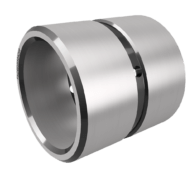

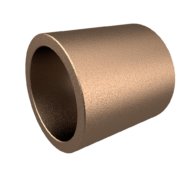

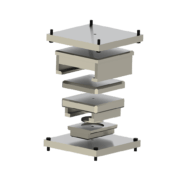

Our LHG155® Bronze exceeded all expectations in the development and showed much higher strength and load values in the first test results than initially required. These high results mean that bearings made of this LHG155® Bronze can be used for heavy-duty applications without any problems, especially where extremely high surface loads (up to 680 MPa static load) act on the bearing point. Typical applications include crane and lifting applications, where forces are generally increased by long lever arms, for example. But also areas in the vehicle or construction machinery industry where, for example, the axle geometry has to withstand higher loads due to the increasingly more extensive superstructures.

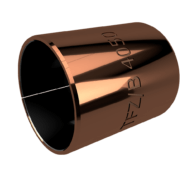

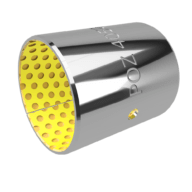

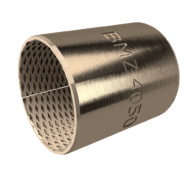

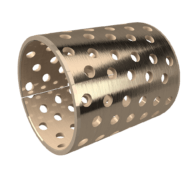

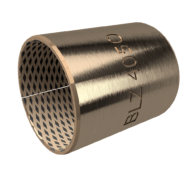

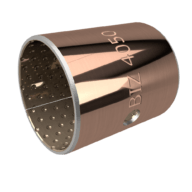

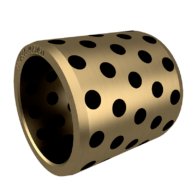

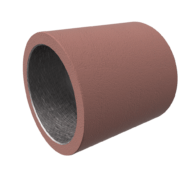

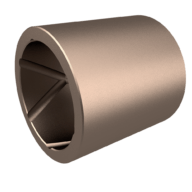

A comparison with other bronze alloys below clearly shows the outstanding mechanical properties of our LHG155® Bronze and the application-specific advantages that can be achieved when using this new alloy. In addition, we can produce the plain bearing design as a maintenance-free version with this new alloy, based on our LUB-MET® products with already embedded solid lubricant plugs. These can, of course, also be designed in a waterproof version, depending on the planned operating conditions. Although the maintenance-free design minimally reduces the specified load values of each alloy variant shown, it still outperforms the plain bearing types made of other non-LHG155® alloys that have been common on the market to date.

A comparison with other bronze alloys below clearly shows the outstanding mechanical properties of our LHG155® Bronze and the application-specific advantages that can be achieved when using this new alloy. In addition, we can produce the plain bearing design as a maintenance-free version with this new alloy, based on our LUB-MET® products with already embedded solid lubricant plugs. These can, of course, also be designed in a waterproof version, depending on the planned operating conditions. Although the maintenance-free design minimally reduces the specified load values of each alloy variant shown, it still outperforms the plain bearing types made of other non-LHG155® alloys that have been common on the market to date.

For further information and questions about our new high-strength bronze alloy, please get in touch with us or send us an email. We would be happy to examine the possible use of this alloy in your planned application areas. But even if you cannot use our LHG155® Bronze, we will be glad to help you select the right plain bearing solution and the suitable plain bearing material for your specific application at any time!