Runs like clockwork – but it’s not!

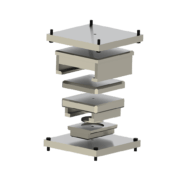

Springer breaks new ground with the V-Sorter

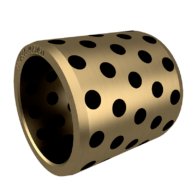

Springer Maschinenfabrik is enriching the timber industry in particular with its product innovations and solutions. In the development of this new log sorting system, the focus was on reducing maintenance and the associated costs and the associated costs. To solve this challenge, Springer turned to its long-standing development partner development partner GLT Bearings. The many years of know-how in the field of plain bearings allowed GLT Bearings to replace many traditional applications, in which expensive roller bearings were still used, with modern plain bearings. Thus, the previously used roller bearings, which had to be lubricated via a central lubrication system, could be lubrication system, could be replaced by maintenance-free alternatives.

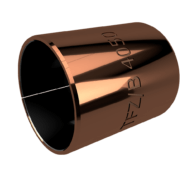

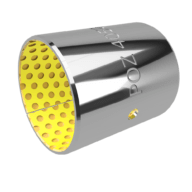

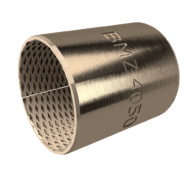

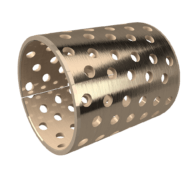

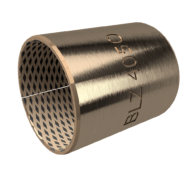

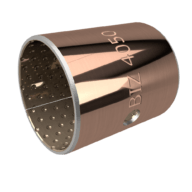

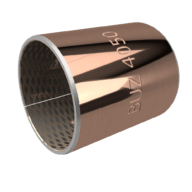

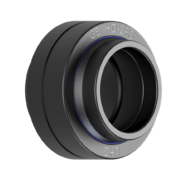

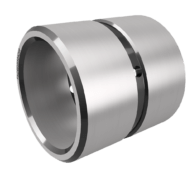

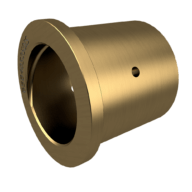

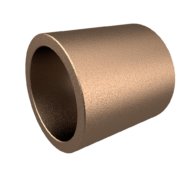

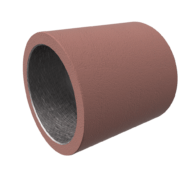

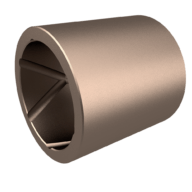

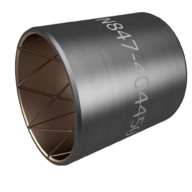

To meet these challenges, GLT opted here for the maintenance-free bearing COM-KU/D403 in special geometries and diameters of up to 320 mm. In addition, a conveyor belt is now used instead of the previously used sliding surfaces, where the chain had to be lubricated with oil. The associated elimination of lubrication thus makes it possible to guarantee average oil savings of 30,000 to 50,000 l/year. From a sustainable point of view, the considerable reduction in oil consumption is not only a financial saving, but also a positive environmental impact, as less lubricant is emitted.

However, the switch to maintenance-free COM-KU/D403 bearings offers even more advantages. The elimination of the central lubrication insert and lubrication lines is accompanied by immense cost savings, production is simplified, and maintenance and running costs are further reduced. Likewise, in connection with the reduction in friction, electricity savings of up to 60% can be realized. Since the maintenance-free bearings have been installed in the step feeder as well as in the V-belt and V-sorter, the advantages that COM-KU/D403 bearings bring with them are of course utilized several times over.

The combination of a well thought-out design and the maintenance-free GLT compound bearings therefore not only enables an increase in efficiency, but also more sustainable production. Both economically and ecologically this innovation will thus bring enormous benefits to sawmill technology in the future.

Advances like these, however, are not only of great importance for the wood industry. As a development partner, we use our wide range and cross-industry know-how to provide our customers with optimum advice and jointly develop innovative solutions.